PRODUCTCBN Wheel

CBN Wheel

Vitrified Bond

CBN Wheel Vitrified Bond

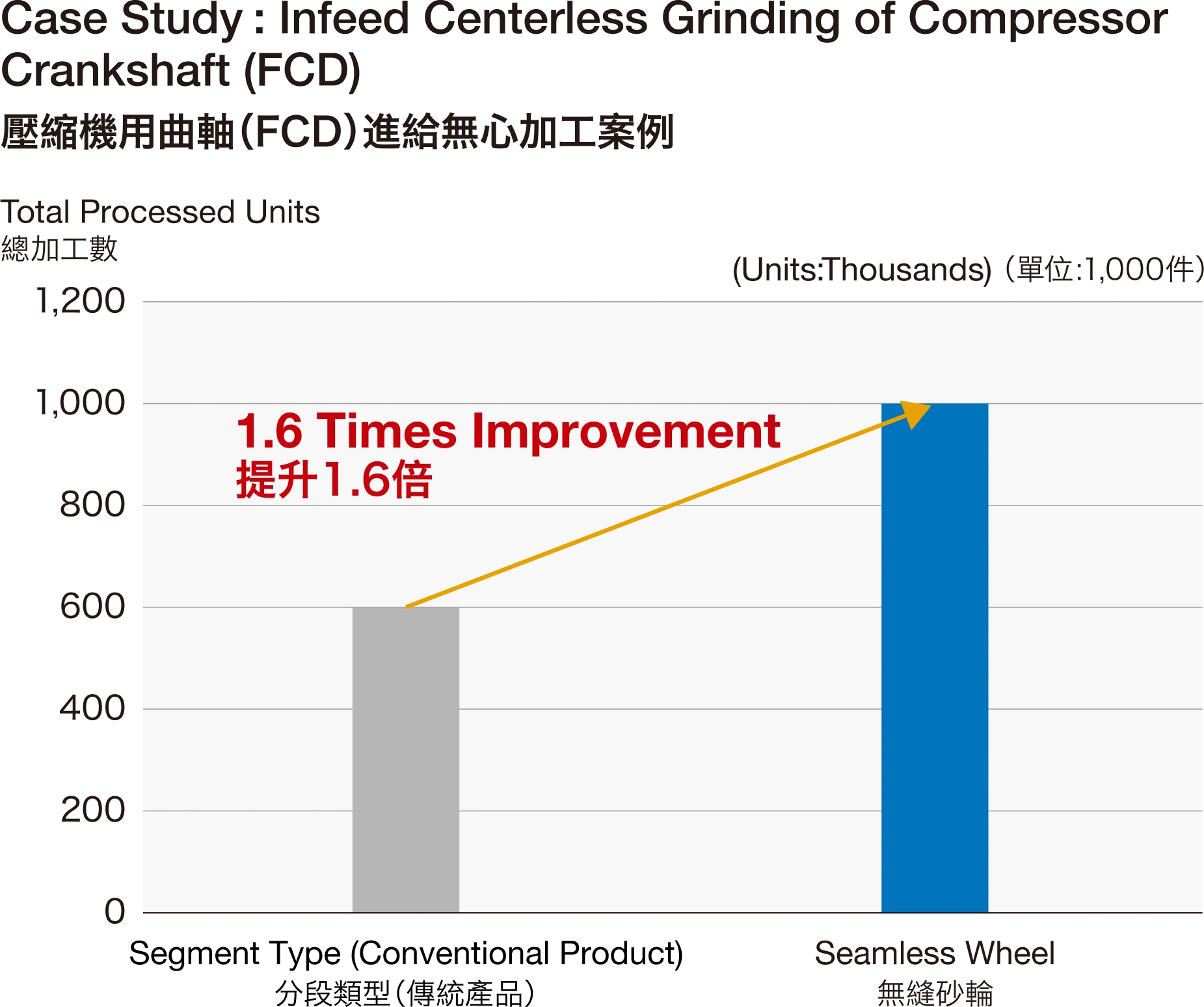

Seamless Wheel

Strong vitrified bond

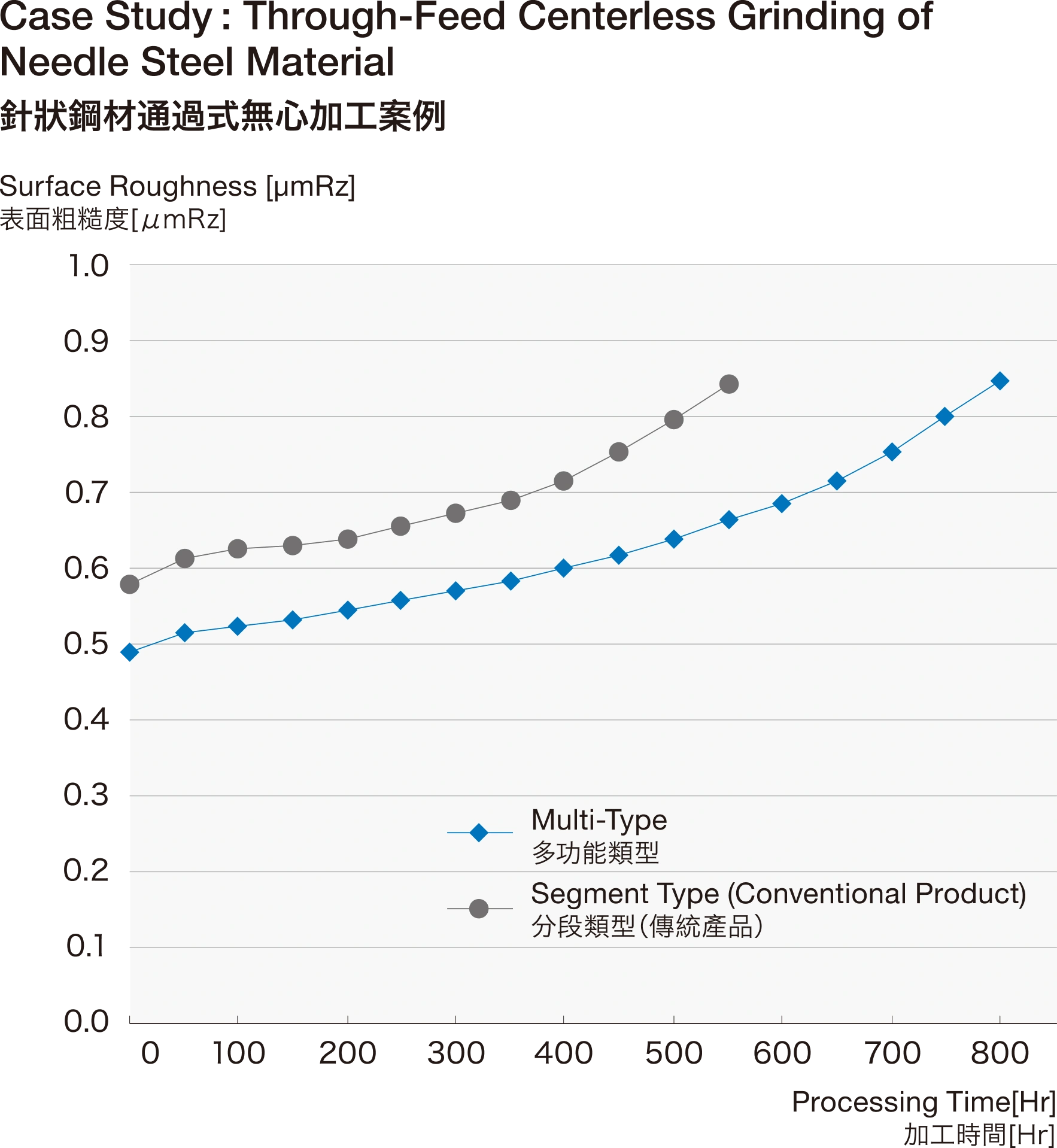

Seamless wheel would provide you fine and precise surface,

comparing with segmental wheels.

It is the best choice for in-feed centerless grinding or plunge grinding.

Grit size from #80 to #500 is available.

Multi Wheel

High-performance CBN wheel for through-feed centerless grinding

Options

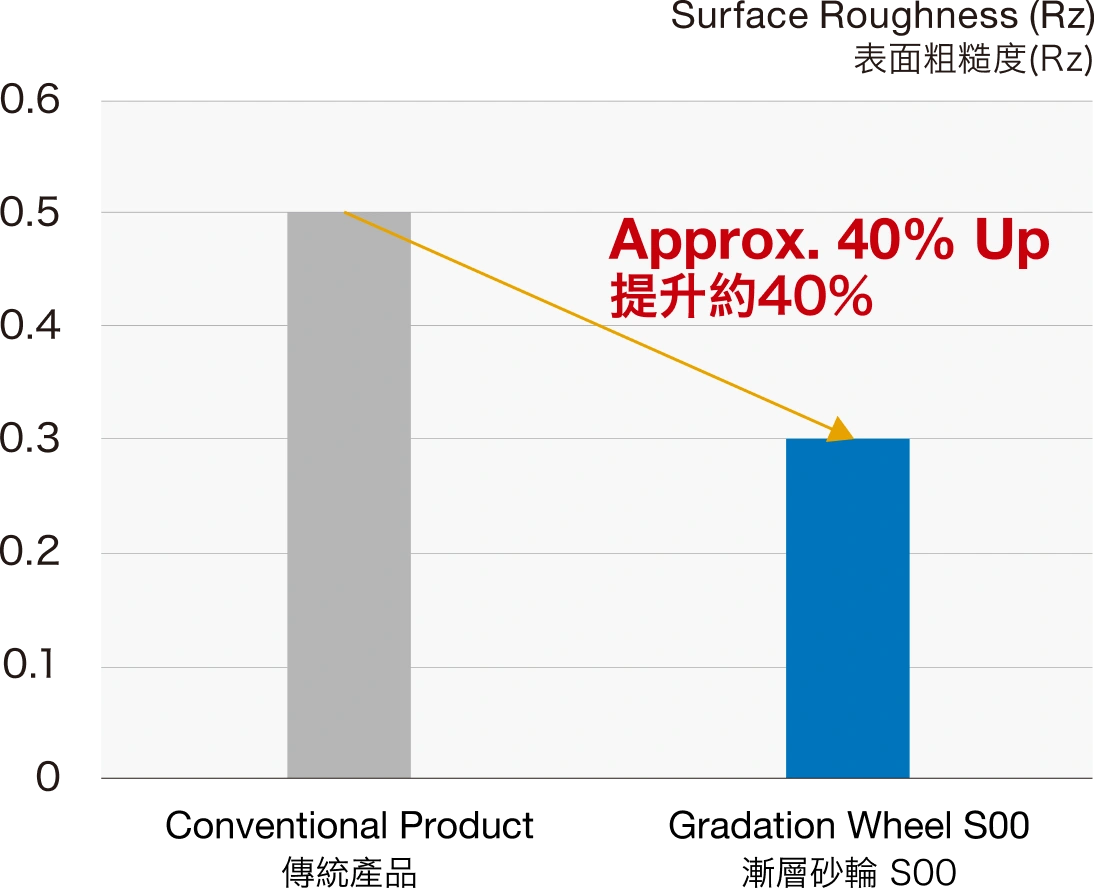

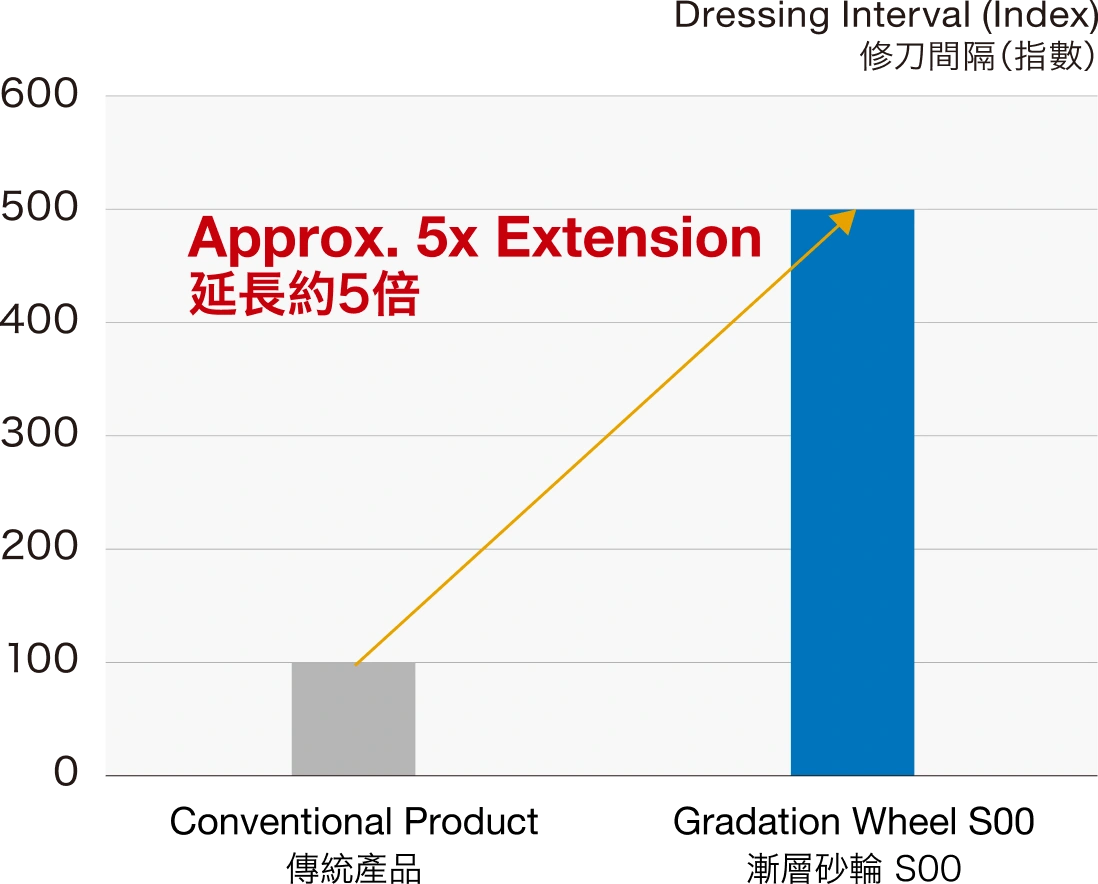

- “Gradation” wheel

Efficiency can be compatible with precision. Just make the inlet part rough, and outlet part fine. - Protective resin plate

Resin plates could be installed on one or both side of wheel. These plates protect wheel from corner’s break and also prevent scratches at inlet/outlet.

C Series

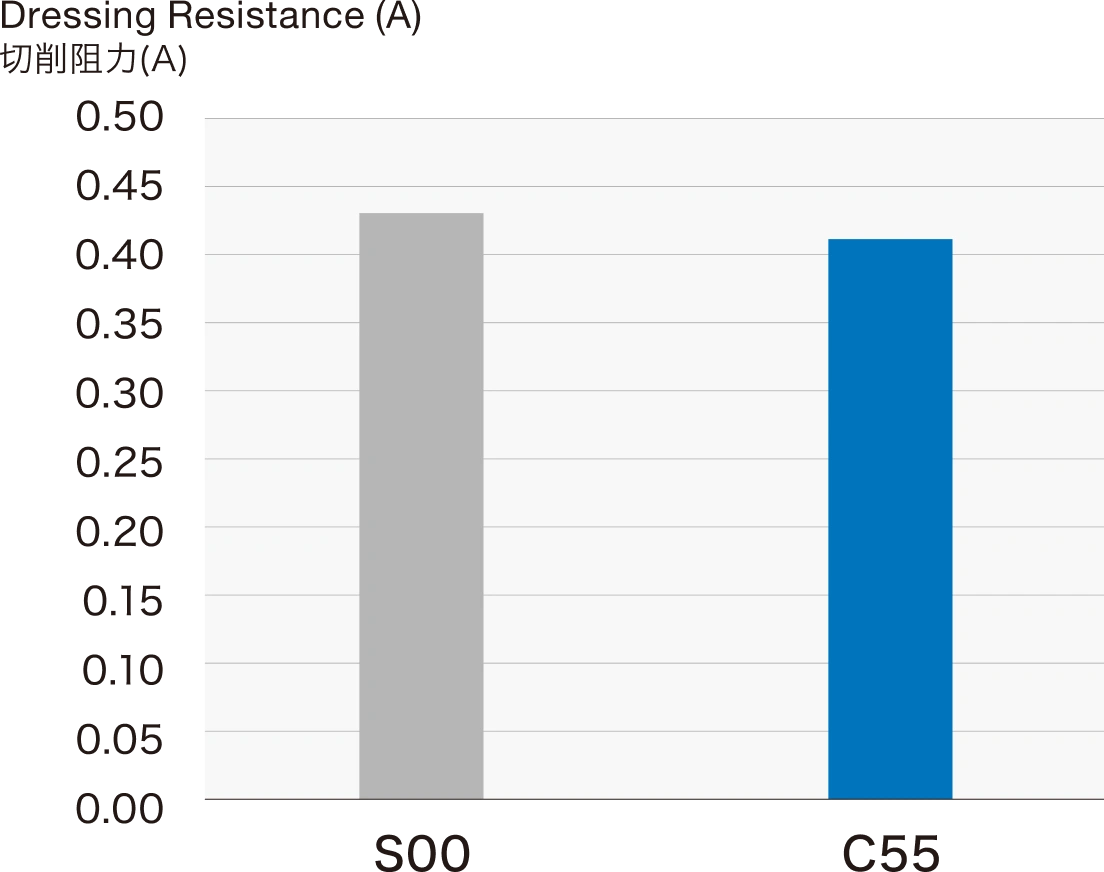

New High-Wear-Tesistant Bond for Super-abrasive

- Enhanced wear resistance extends tool life.

- Supports high-load processing with superior strength.

- The design ensures easy handling with low resistance in truing and dressing processes, even for products with high bond strength.

Dressing Resistance (Measured Value)

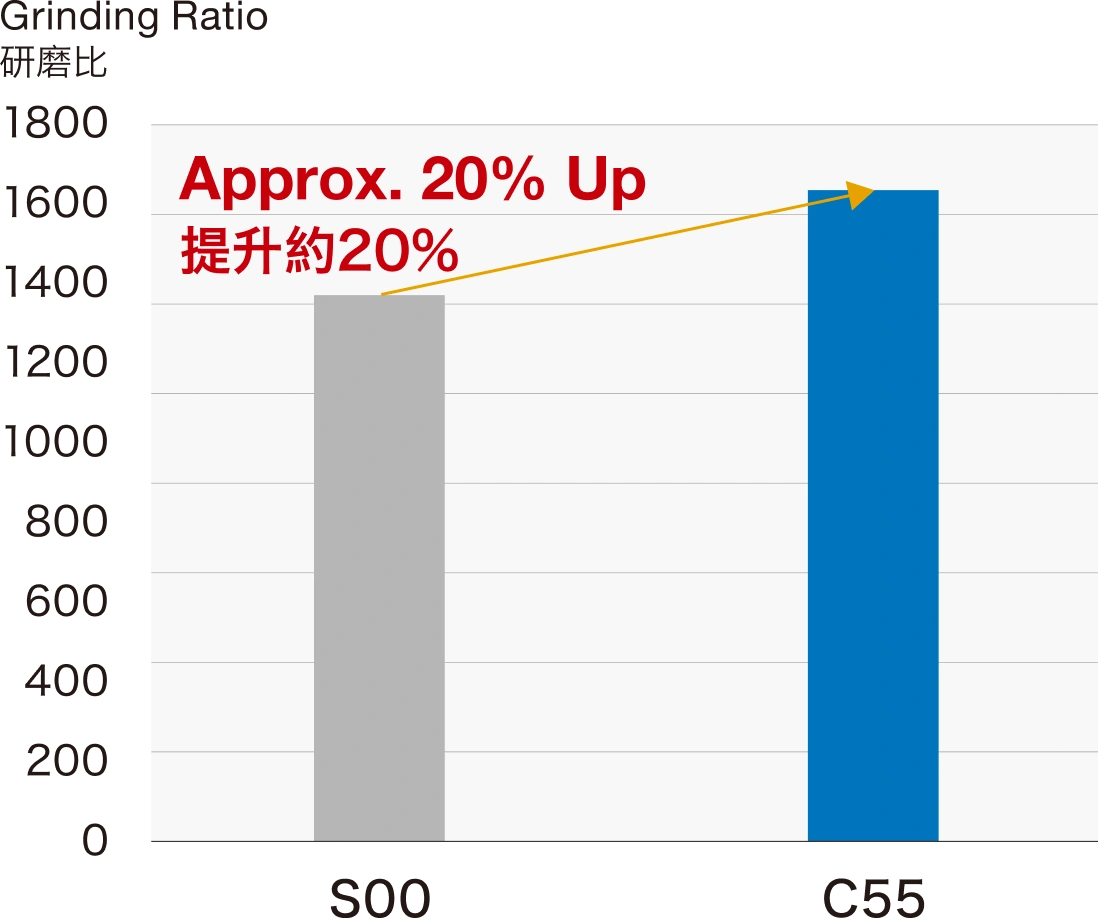

Wear Resistance (Measured Value)

00 Series

S00/F00/P00

High conc. CBN vitrified bonds

3 excellent features

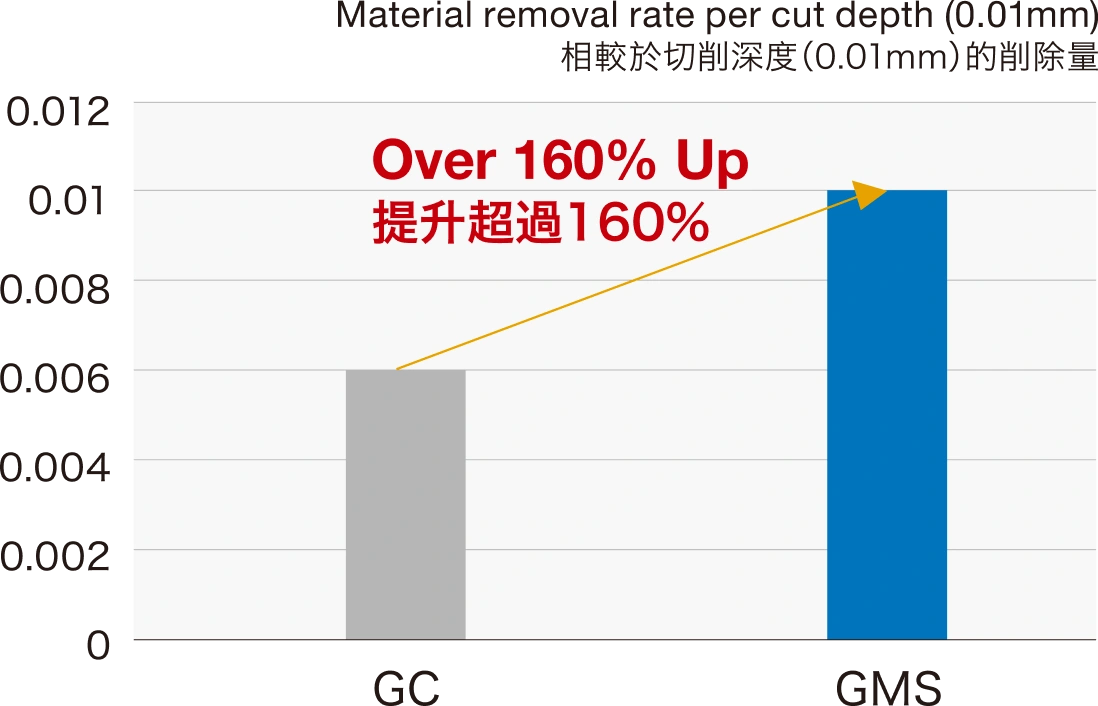

- Easy to dress

Directly follows a change in depth of cut or feed rate of dresser. You may adjust your wheel to get sharpness or fine surface roughness. Sharpness

It is made of well qualified grain and bond to provide you excellent sharpness. Hardness grade “J” is available for applications those require especially sharp-cutting.- Stability

Our forming process is well practiced to make CBN section homogeneous, so the performance would be good and stable.

Recommended applications

- S00:Centerless, P00:OD grinding,

F00:ID grinding *Requires dressing equipment for super abrasive wheels.

S Series

S11/S12/S13

Excellent sharp cutting & form holding.

Middle to high conc. c-BN vitrified bonds.

Features of S Bond series

- Less burns and precise dimensions.

- Bonding is strong, so fine surface roughness and good geometric accuracy could be obtained.

- Suitable for applications requiring good form holding, such as vane or ID of bearing steel.

Recommended applications

- Centerless grinding, OD grinding,

ID grinding *Requires dressing equipment for super abrasive wheels.

M Series

M11/M12/M13

Low conc. CBN vitrified bonds. -Pursuing usability-

M series is designed to enable dressing and truing by single point diamond dresser. Its conc. Is low concentration. It is applicable to conventional grinding machine as well.

M series may be a good solution for tool steels which have hardness over HRC60 or hard-to-grind materials such as stainless steels.

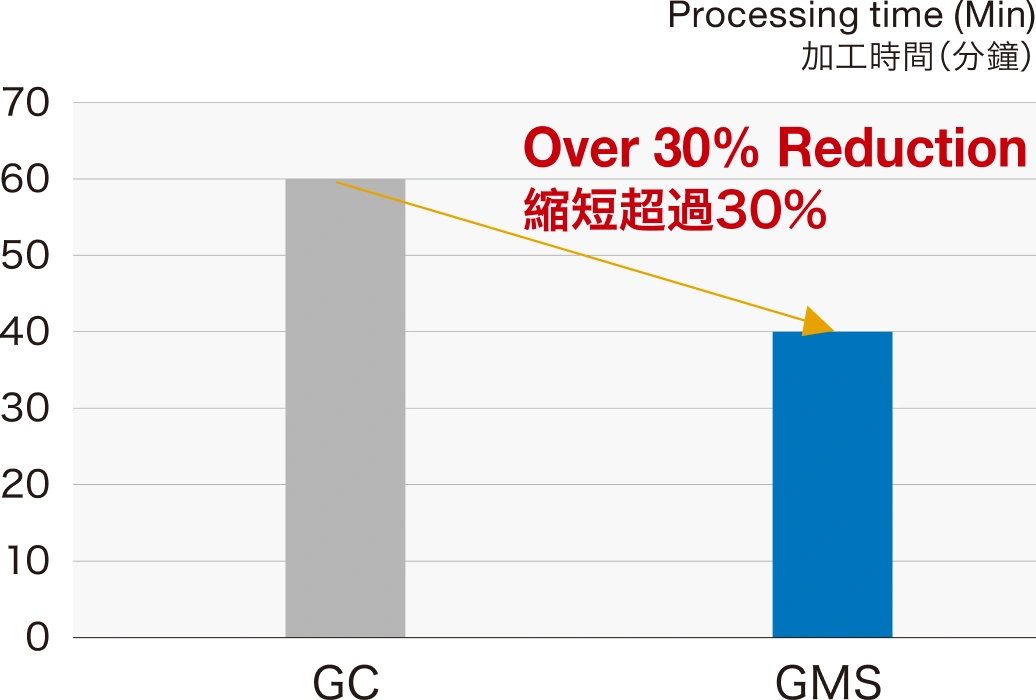

- Saving machine time

High quality CBN grain allows grinding efficiency much higher than conventional wheel. - High precision

Sharp cutting would provide high accuracy in dimensions and geometry. - Less wheel wear

Even comparing with sintered alumina grain, M series exhibit much higher grinding ratio.

Recommended applications

ID grinding, OD grinding, Jig grinding, surface grinding

nternal grinding test of SUS440C conducted in-house

CBN Wheel

Resinoid Bond

CBN Wheel Resinoid Bond

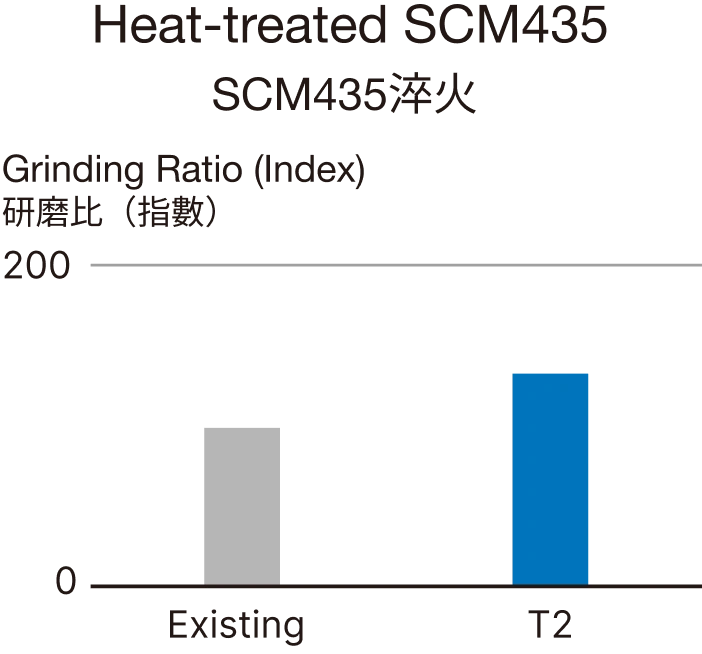

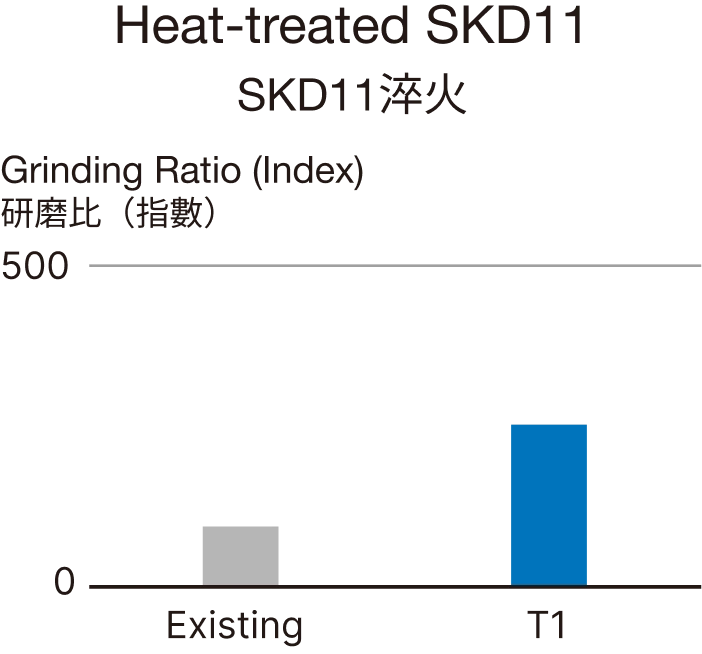

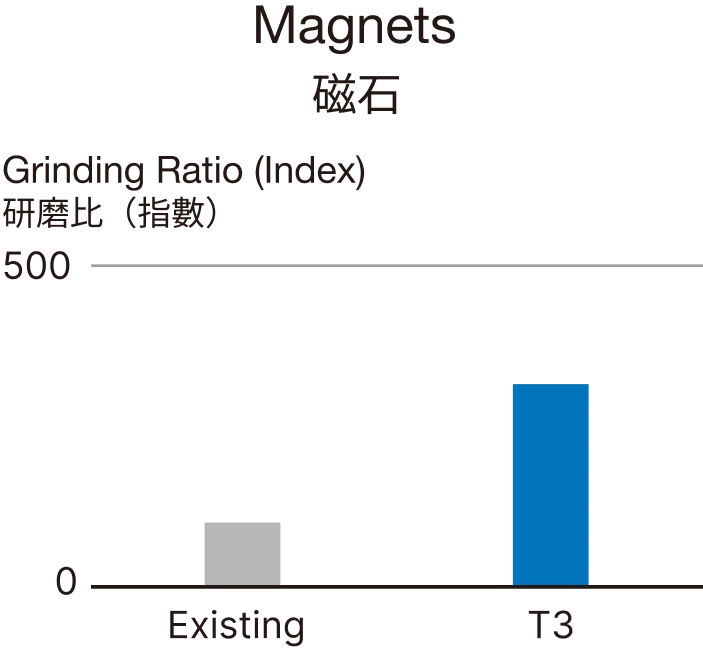

T Series

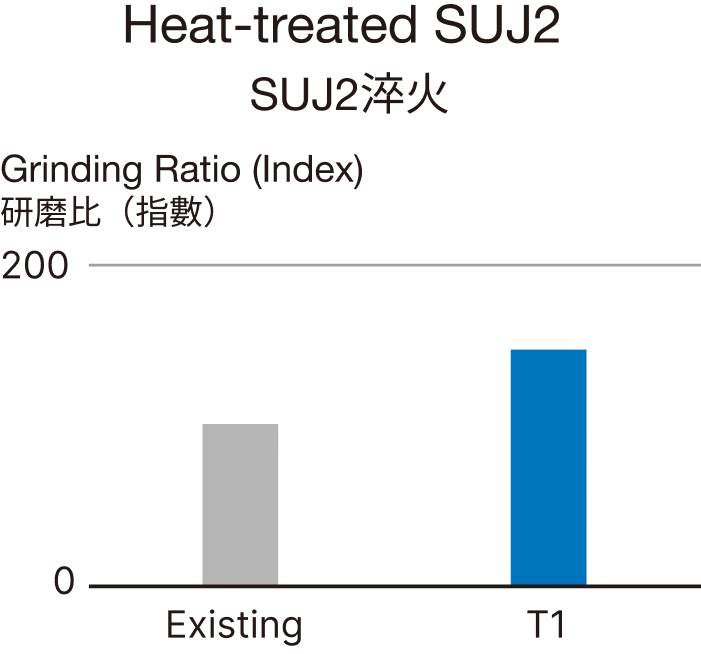

New Bond Designed for Specific Workpiece

- New bond design optimized for chip

removal - Improved tool life achieved through

superior wear resistance

| Bond Name | TI [For hard materials] |

T2 [For medium hardness materials] |

T3 [For materials producing powder-like chips] |

| For Ferrous CBN materials |

For high-hardness hardened materials Heat-treated SUJ2 Heat-treated die steel |

For medium-hardness hardened materials Heat-treated SCM steel Heat-treated carbon steel |

For cast iron materials (Raw Gray Cast Iron (FC), Heat-treated Ductile Cast Iron (FCD)) Sintered materials |

| For Non-Ferrous SD materials |

Magnetic materials Various ceramics |

||

| Test Results |  |

|

|

|

|

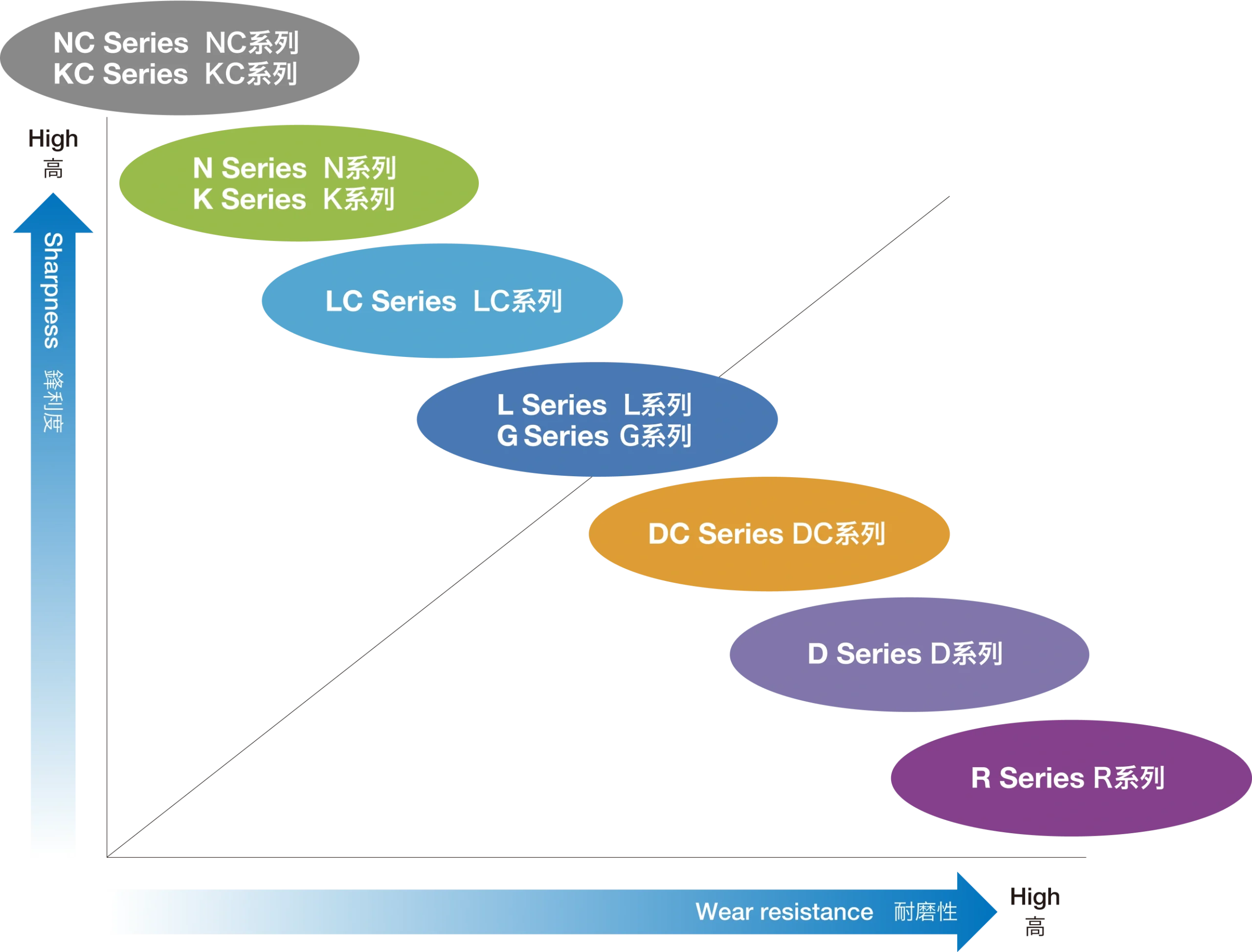

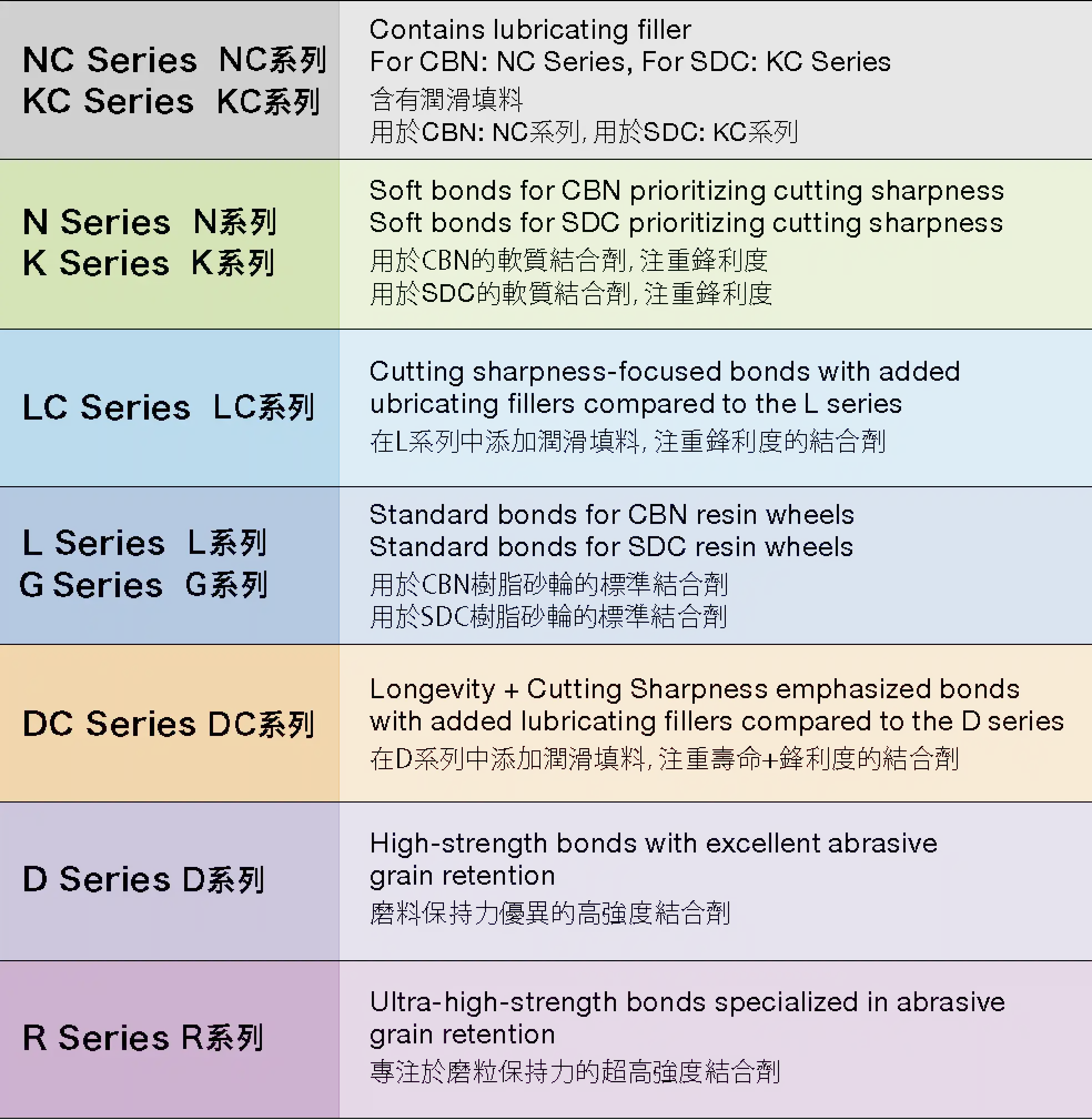

LC Series

LC1/LC2/LC3

DC Series

DC1/DC2/DC3

NC Series

NC1/NC2/NC3

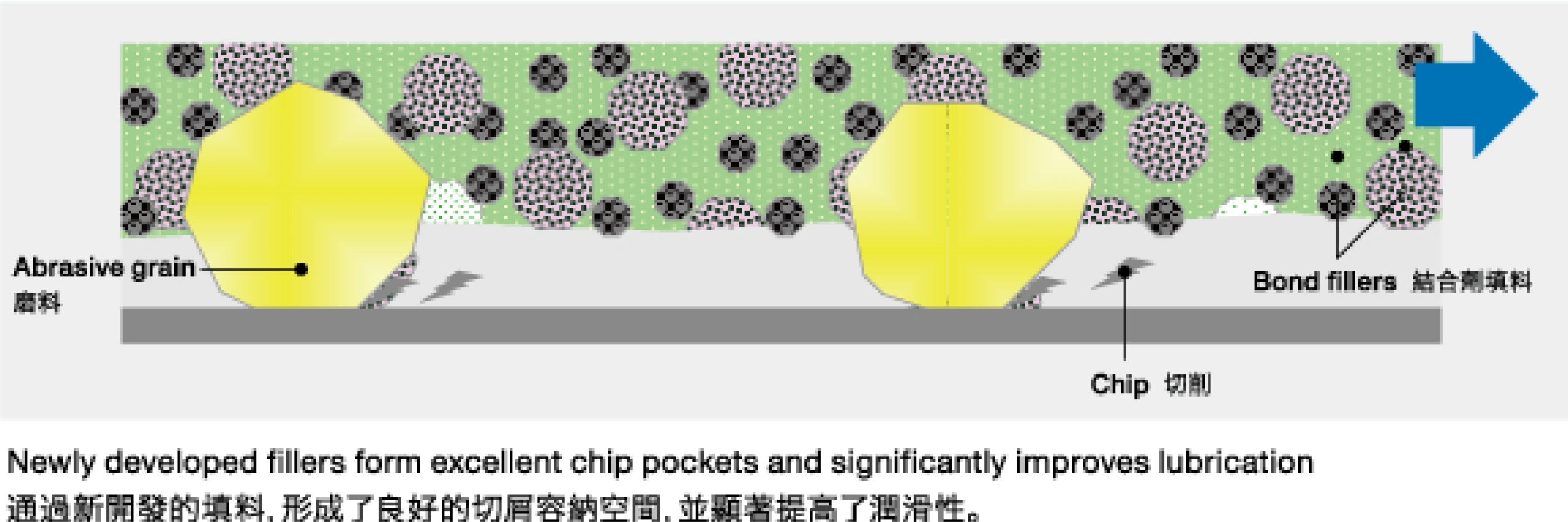

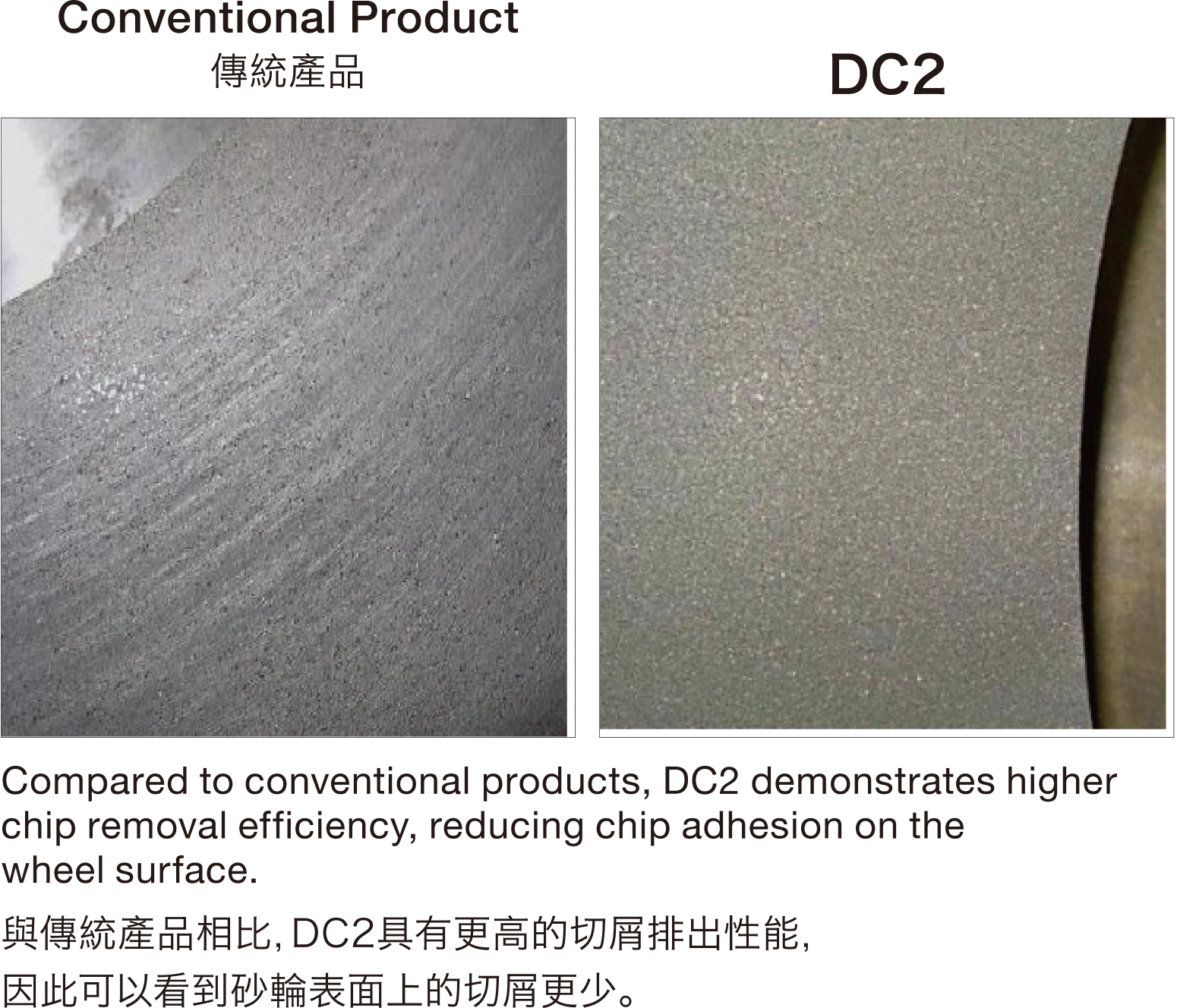

Ultra-high performance CBN wheel that achieves both superior

cutting sharpness and extended tool life

Features of LC bond /DC bond /NC bond series

- Add special bond filler

Good truing/dressing properties.

The bond matrix retreats easily, ensuring a stable amount of protrusion of the abrasive grains and extending the interval.

Recommended grinding application

LC Series : Balance type

Recommended to Double-disk surface grinidng, Cylindrical grinding, Centerless grinding.

DC Series : Focus on wear resistance

Recommended to Double-disk surface grinidng, Cylindrical grinding, Centerless grinding.

NC Series : Emphasis on sharpness

Recommended to Constant pressure grinding, Spring grinding, Hard brittle material processing, Fine grain processing.

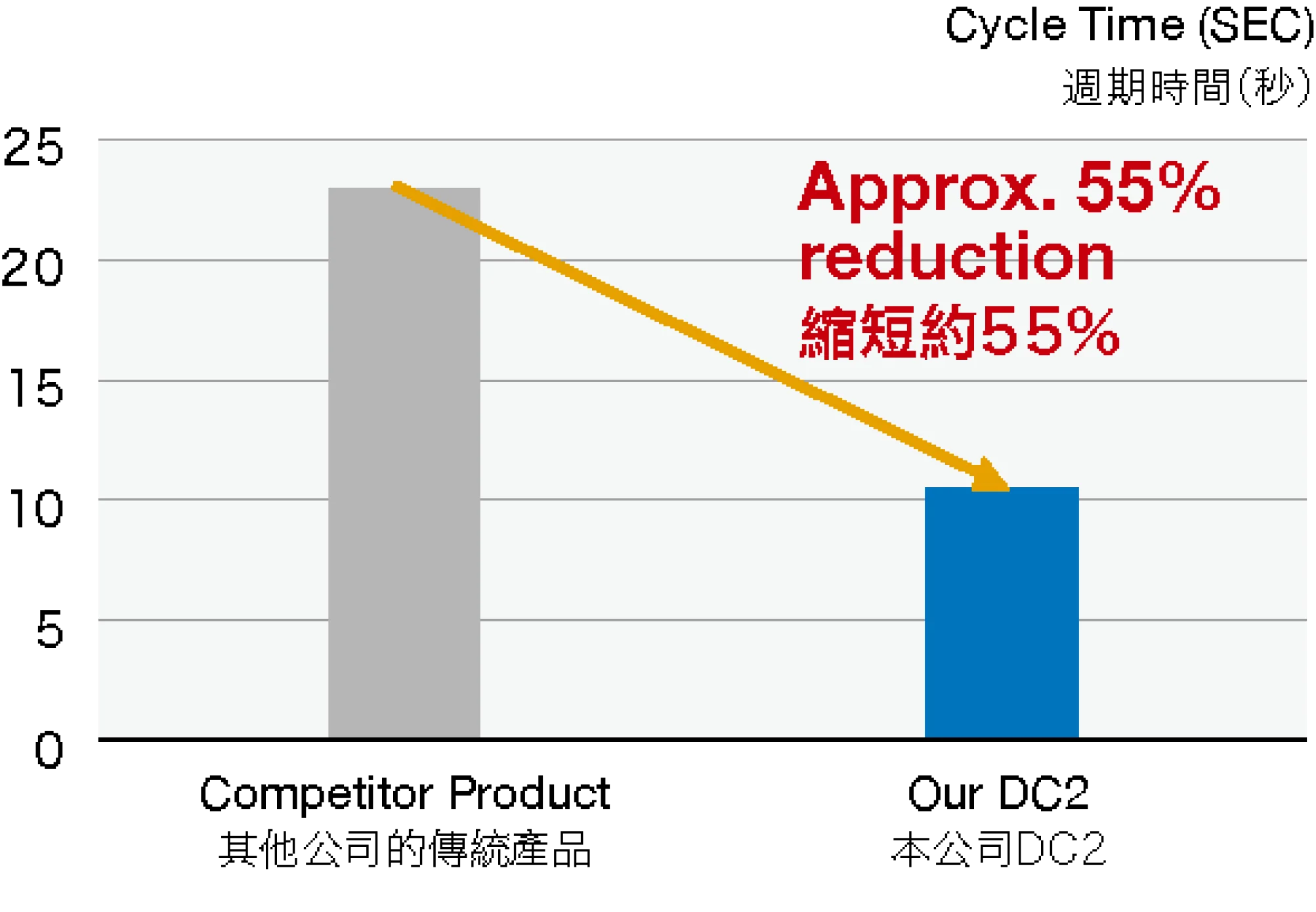

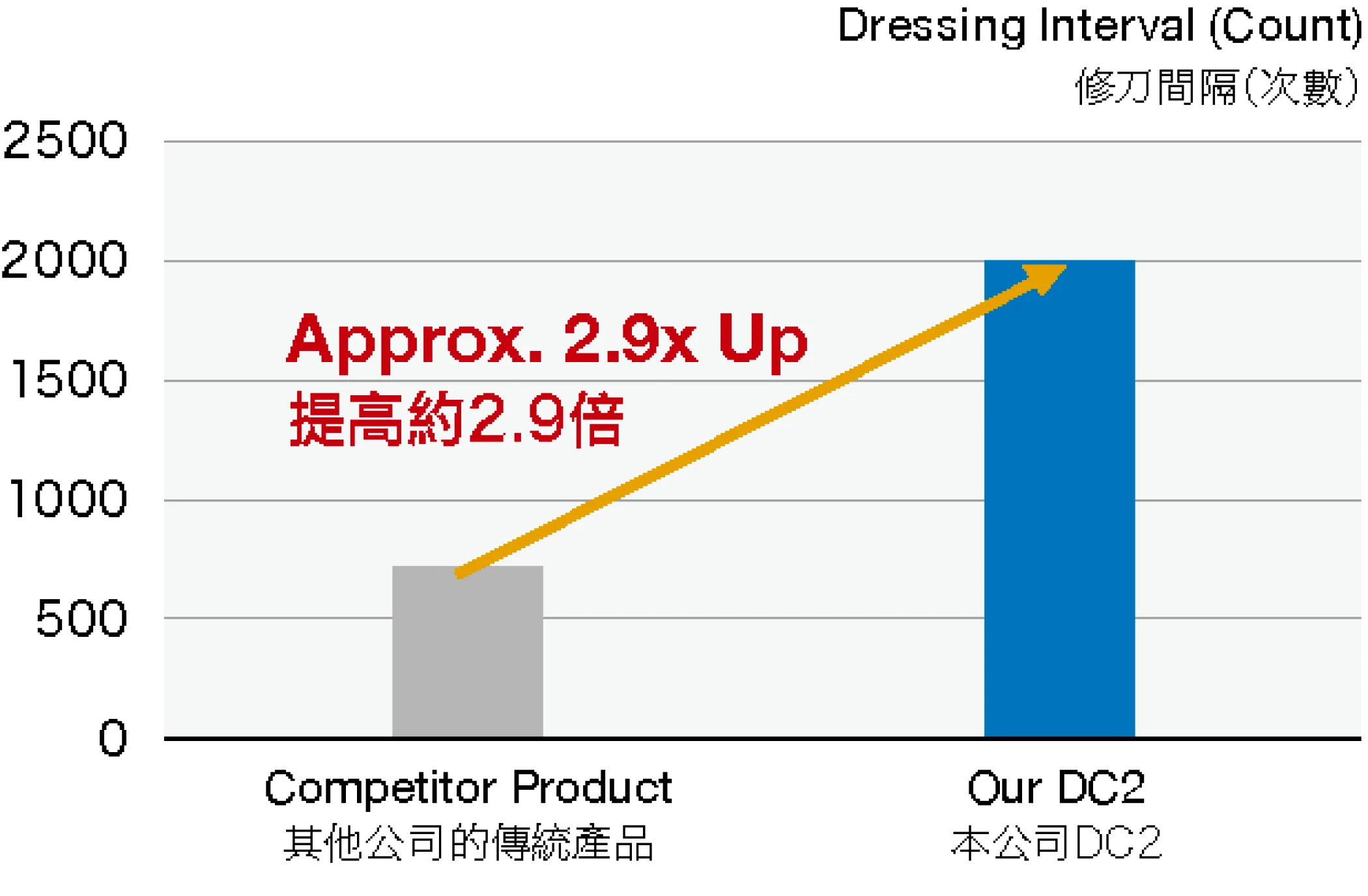

Case study: Double-sided surface grinding for automotive components

(ferrous sintered material)

L Series

L10/L20/L30

Standard CBN wheel with a proven track record

- L series have been used successfully in various applications.

- Mostly applied to compressor parts, automotive parts, bearing parts and so on.

D Series

D10/D20/D30

Long life CBN wheel

- Durability enhanced from L series.

- Thermally stable resin holds grains strongly. Effective to both rough and fine grit size.

N Series

N10/N20

CBN wheel specialized for sharp-cutting

- Grinding resistance would be kept at low level by self-sharpening effect.

- Avoid grinding burn because grinding resistance is low.

- For example, residual removal stock was smaller in case of coil spring grinding.

■Main Lineup of CBN Resinoid Bonds