PRODUCTGeneral Wheel Vitrified Bond

General Wheel Vitrified Bond

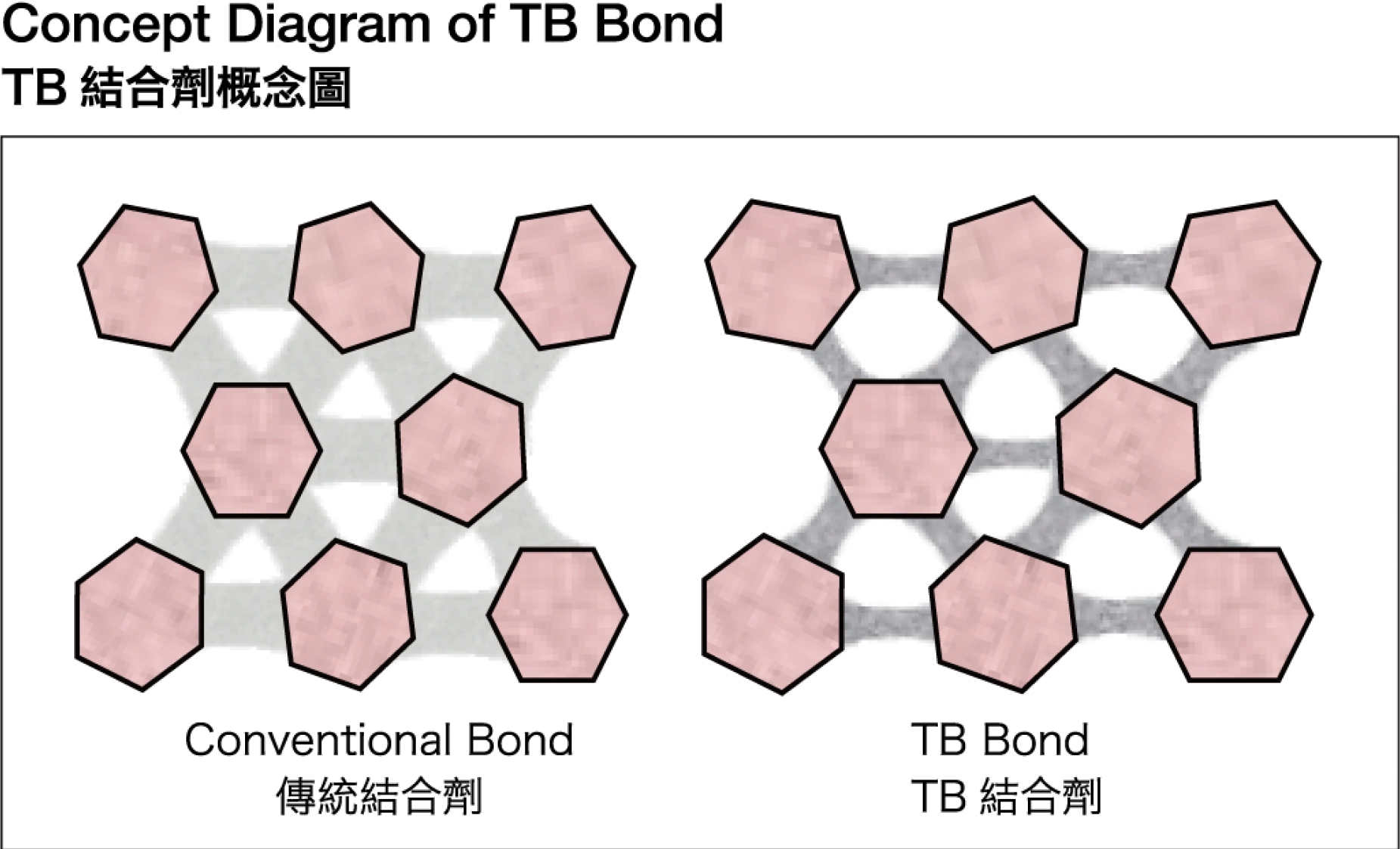

TB Tough Bond

High-strength bond

Features of TB bond

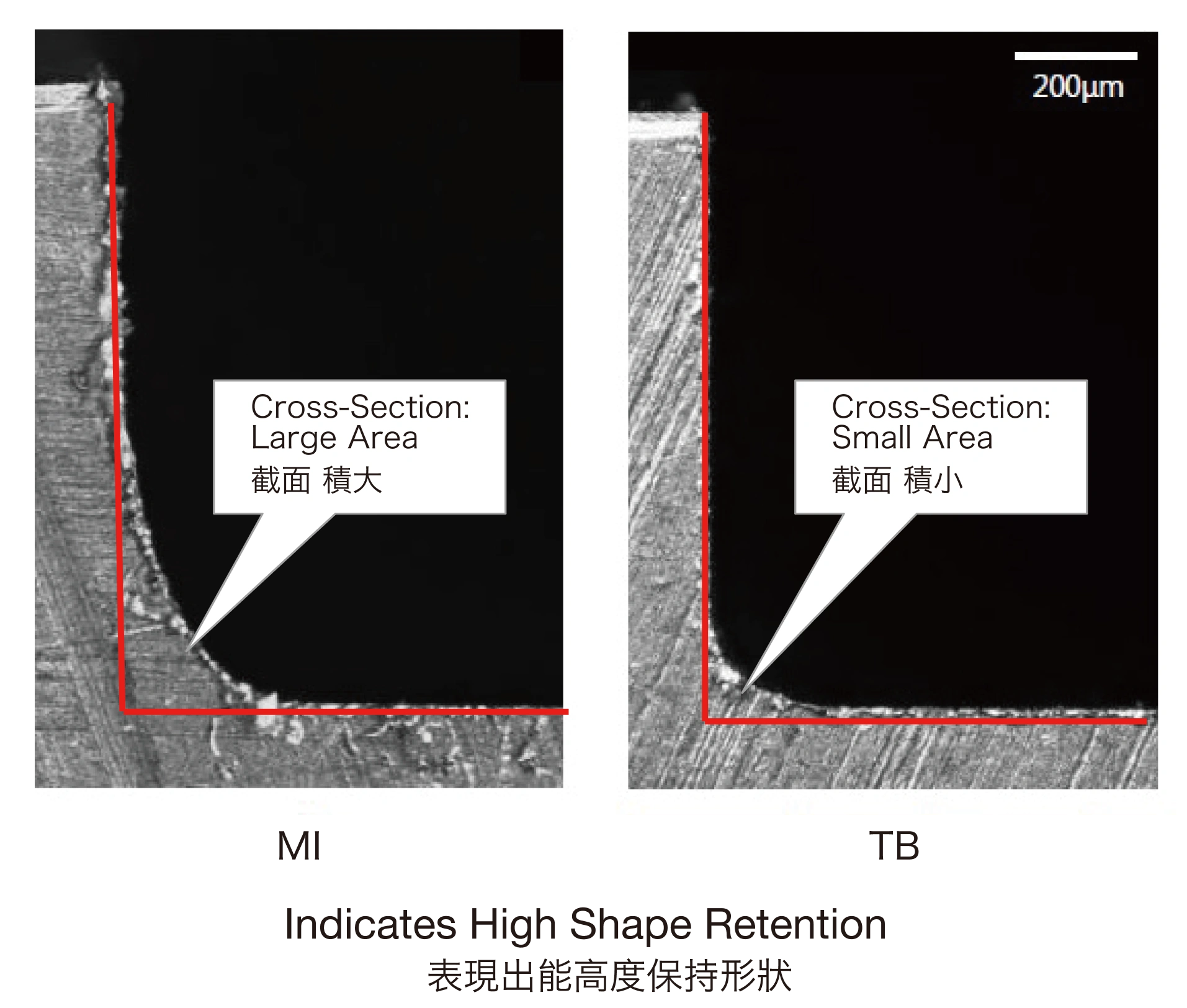

- High Shape Retention

Strong abrasive retention minimizes wheel deformation - Unlocks the Potential of sintered Alumina grain

Sintering process maintains the microstructure of sintered Alumina High Rotational Strength: Enhances safety during high-speed grinding

Recommended applications

- Crankshaft grinding, angular grinding, groove grinding, cylindrical grinding (plunge cutting), etc.

Range of applicatioin

- Grit Sizes: F46~F220

MI

Standard precision bond for grinding wheels

Features of MI bond

- Reduce grinding resistance

We propose the most suitable grinding wheels tailored to your application needs.

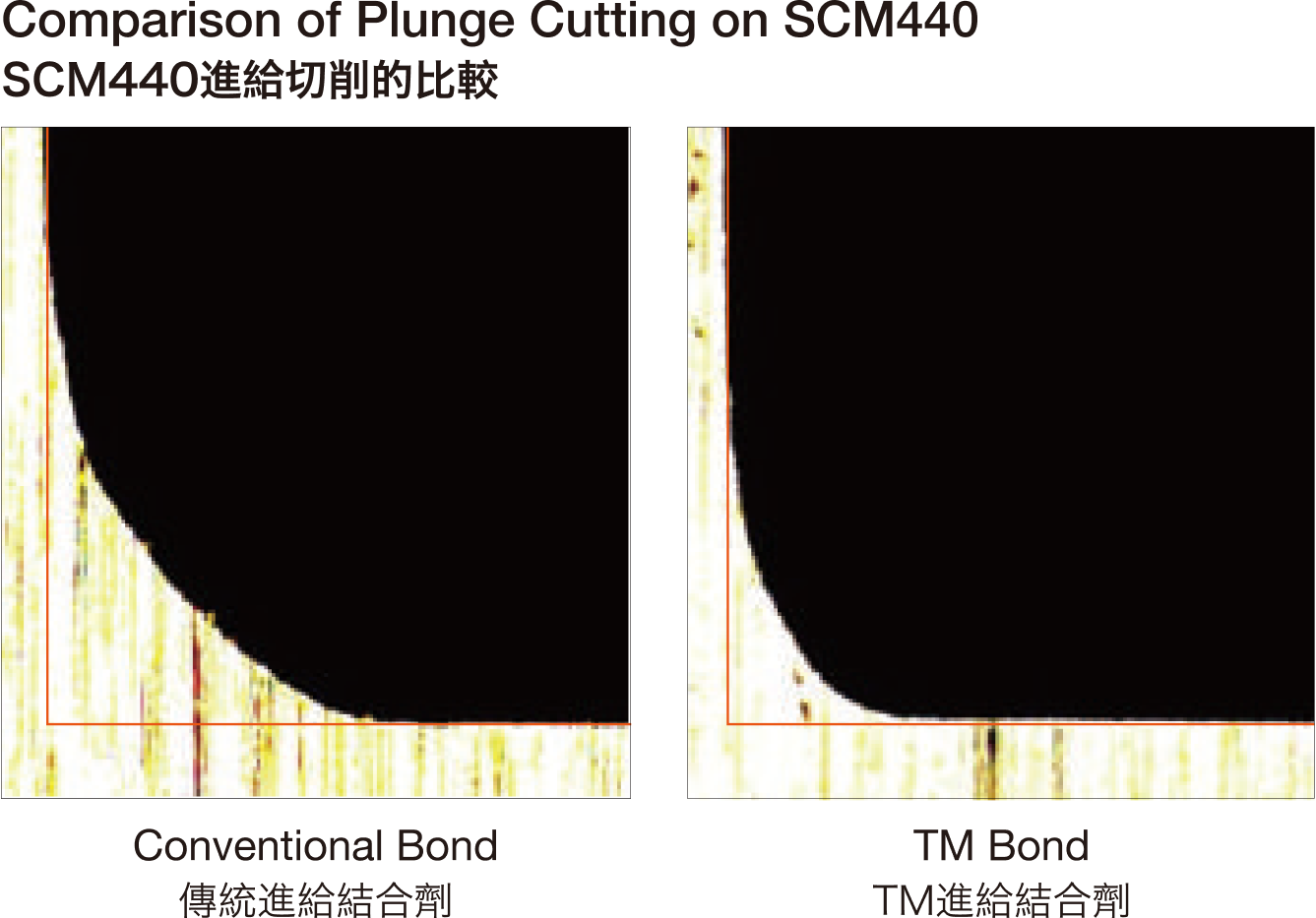

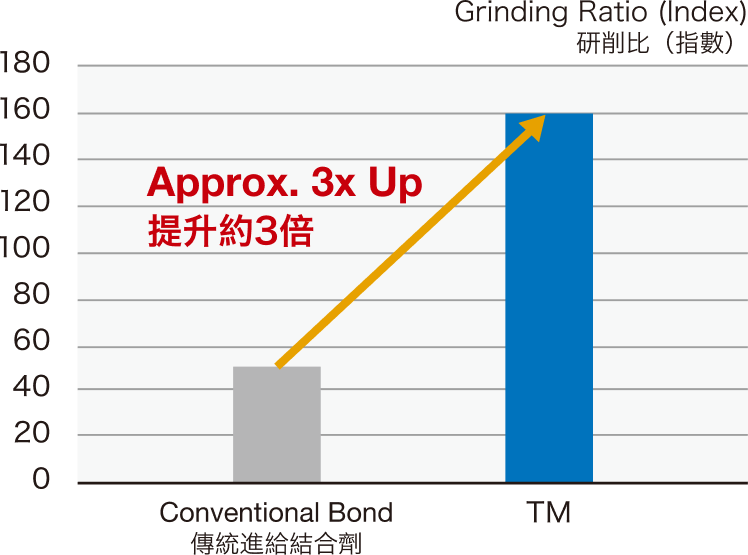

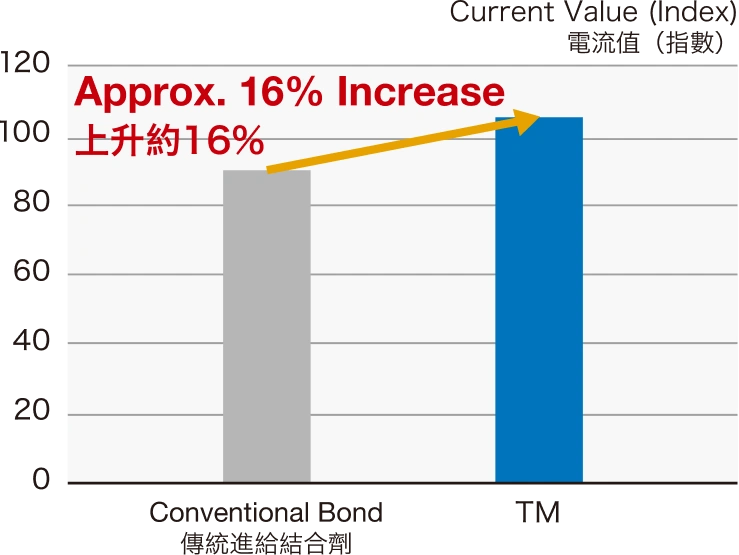

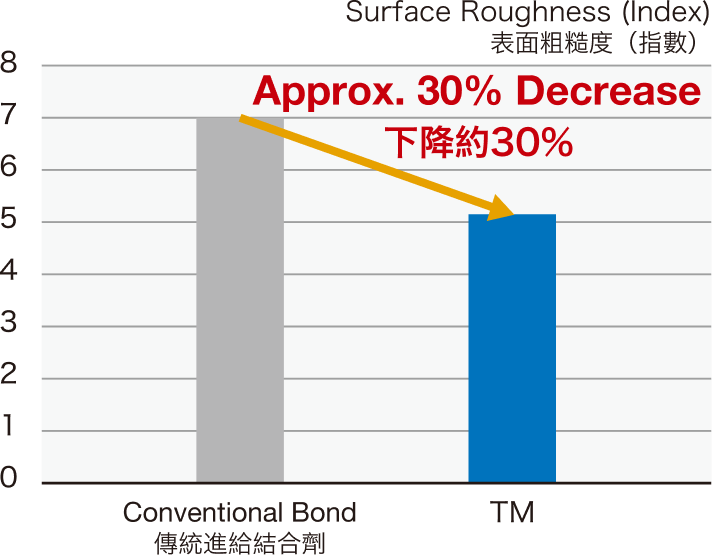

TM Tough Matrix

Strong vitrified bond

TM bond has improved strength from conventional bond, so we can make grinding wheel of same hardness grade with small amount of bond. Friction between bond and work piece is less, performance of grain is maximized. TM is applicable to fused alumina grains only. Combinations with CS series are good choice to start with.

Features of TM bond

- Excellent form holding

- Stable and fine surface roughness

- High rotational strength. Safe.

Recommended applications

- Cylindrical grinding, Crankshaft grinding, angular grinding, in-feed centerless grinding

Internal Test with the Same Amount of Bond

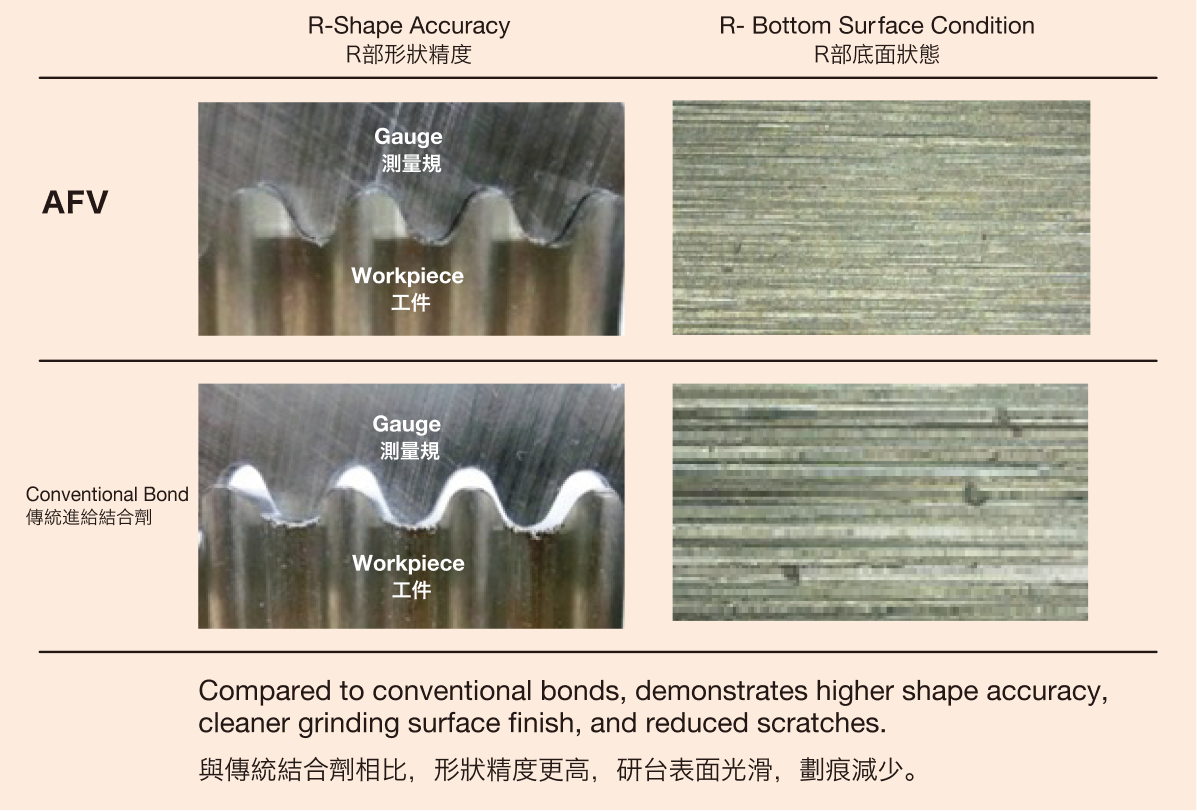

AFV/CFV

Vitrified bond with a new concept. Soft-touch and smooth self-sharpening.

AFV:bond for alumina abrasive

CFV:bond for SiC abrasive

Features of AFV/CFV bond

- Wheel wears evenly, so the wheel may keep its form.

- Low grinding force, less welding of material. Suitable for hard-to-grind materials like Inconel.

- Shrinkage in firing is small, so fine grit size and porous structures are available.

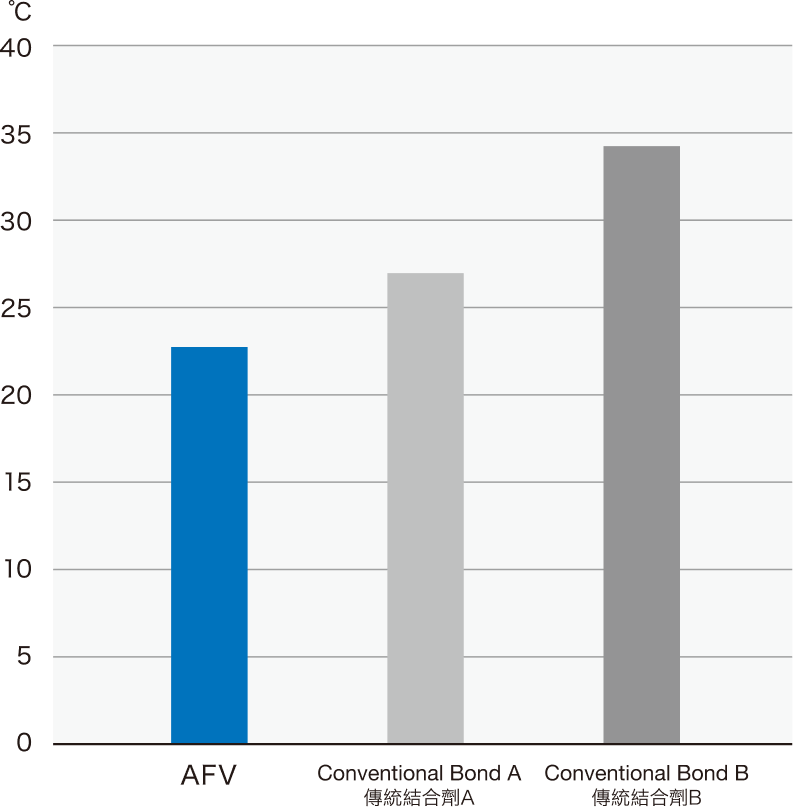

Grinding Test on Inconel Material

Temperature Change of Workpiece Before and After Grinding

General Wheel Resinoid Bond

Resinoid Bond Wheels

Our resin bonds are combinations of various resins and fillers. Bond recipe is adjusted to your requirements.

We have a lot of experience and past records, especially in double disk grinding and centerless grinding.

■Main Lineup of Resinoid Bond

| Applications | Focus on Sharpness | General Purpose | Focus on Wear Resistance |

| Centerless | 5AM 5AB | ||

| Cylindrical | |||

| Springs | |||

| Fine Grit | 3IA | ||

| Disk | 5LT 5JS | 5IS 5ID | BEX |

| Ring | |||

Airy

Smooth Cutting Performance

Features

- Good self-sharpening would keep grinding resistance low.

- Recommendable for grinding high hardness steel.

- Stable self-sharpening is useful to through-feed double disk grinding or roll grinding.

- Spec. such as grain combination is widely customizable to improve performance.

Recommended applications

- Double disk grinding of hardened steel parts

- Roll grinding

BEX BEL Extra

Opening New Horizons in Resinoid Grinding Wheels

Features

- Its porous structure leads to sharp-cutting.

- BEX bond holds grains strongly, so the wheel life is longer than ordinary resin bond.

- It is highly resistant against heat and water, so the performance is stable throughout the year.

Recommended applications

- Surface grinding of mild/tempered steel (cylinder type and disk type)

Case Study: Double-Sided Grinding (Carrier Through System) of Cold Rolled Steel Sheets